(This text was updated in August 2018.)

Despite being top model of the V-series, the V-1 has overly simple record alignment settings. Bias for metal is set via two variable capacitors, one for each channel. These capacitors pass more or less bias current from the oscillator to the head. The bias settings for type I and II are mono, and act on the oscillator's supply. There is some interaction: you have to align bias for type IV first, and only then for II and I. Further, there is only one set of left/right record level potmeters. All of this means that the deck can be set up properly (bias and level) for just one tape, and bias-only for two others. This does not bode well for Dolby compatibility ...

I intended to set bias for minimal distortion, and then, if necessary, adapt the record equalisation to obtain a flat-ish record/replay response, with a treble rising in accordance with the replay curve obtained in part 1 of this series.

Doing so I found it very hard to get third harmonic distortion low. Even at 200nWb/m (ANSI) there was 0.8% in the left channel, and some 1.2% in the right channel. Increased input levels quickly deteriorated the situation, 3% distortion being reached at 2dB over Dolby level. With metal tape!

A further curiosity was that there were also significant amounts of second harmonic distortion, which does not belong in tape recording.

Digging around on tapeheads revealed that circuit switching often was done with a special type of bipolar transistor. These so-called muting BJTs are more or less symmetrical, meaning that their collector and emitter roles can be swapped. Apparently it was not unusual at all that the control of such transistors was done wrong in cassette decks, leading to unnecessary low overload ceilings of the electronics. Strange, when doing it right does not cost more.

The V-1 uses four such transistors to switch the record equalisation networks (Q106 and Q107 in the above diagram). Cutting the traces of their base leads and bridging them SMD-style with signal diodes (red in the diagram) brought the distortion down, now reaching 3% with metal tape at +6dB, and with type II tape at +4dB. Moreover, any trace of second harmonic distortion disappeared.

Following this a new attempt at setting the recording side was done. The results are below. While it was possible to get reasonably balanced and symmetrical traces for metal, type I and II showed high treble losses in the left channel. The mysterious thing here is the channel imbalance with I and II, while IV seems OK.

During these measurements sometimes one or the other channel would get instable, with suckouts appearing periodically in the frequency response traces. I found that the deck does not erase very well. I reaches -30dB or so. Presumably the suckouts were caused by recording a fresh sweep over an older measurement signal. I found no reason for the lacking erasure (maybe the head makes bad contact with the tape, to be investigated!).

Perhaps I had been a bit impatient, and was the deck simply not ready yet for the end game. From day one there had been intermittent problems with pots and switches. The pots were easy enough to fix, they are accessible, but it appeared very hard to get to the six push buttons for tape type and noise reduction. In the end I flipped the deck upside down and sprayed liberally Kontakt 60 over the switch board, operated the buttons a few tens of times, then let it dry for a day.

Next I spent some time polishing the heads with Brasso. They seemed spotless before I started, but positively shiny when I was done, with the (minor) wear path now for the first time visible (see picture, which reveals more than the naked eye or a loupe). I also made a crude tape path checking cassette, and the V-1 played it perfectly (for reference, there was so much tape guidance removed from the shell that my A-550RX, with its smooth transport, has the tape derail within seconds). I measured wow& flutter with WFGUI and it was below 0.035% RMS weighted, an excellent result for a nearly 40 years old machine!

Back to the issue of biasing then. Remember that the metal bias level is set through two variable capacitors. Until now right bias always ended up at the maximum, and even then seemed short. Left bias was set much less. Worried by this apparent imbalance (if the head is OK then surely both channels need roughly the same bias), I measured the actual bias signals at the capacitor terminals. This showed that, for unknown reason (capacitor mismatch, different head load?) the right channel bias was 10% less than the left channel's, even with the alignment set to maximum. This obviously skewed the record frequency response (so far hidden by the redundant playback correction in the left channel) as well as the record level balance. I then tweaked the left bias capacitor until the signal to the head more or less matched the right channel. This would be my starting point for further alignment.

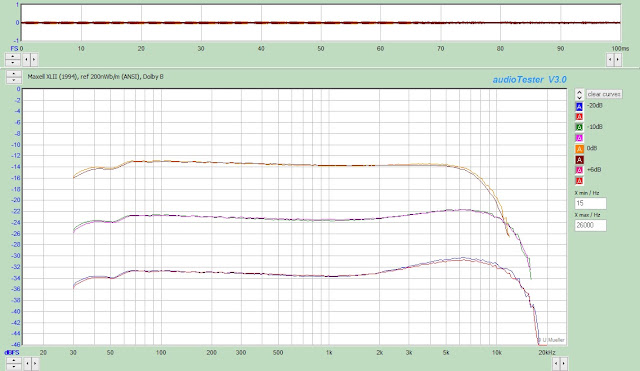

Considering that I would not likely use metal tapes for recording on the V-1RX (after all it can't hammer like a Nak!), I jumped straight to Maxell XLII (from 1994, the grey one), first using the shared type II bias potmeter, then tweaking the left bias capacitor for balance, followed with setting record levels for both channels. The results are below for different recording levels, no NR, Dolby B, and dbx.

(Note that all of this was done before I changed the playback equalisation from 130 us to 150 us. So in reality all curves have a bit more treble than shown here below.)

This seems very reasonable. Dolby tracking is nice, even though the highest treble is missing (yes, I removed the fixed MPX filters from the recording Dolby circuits). The dbx responses amplify any response error, as expected. Incidentally, the measured MOL (400Hz, 3% third harmonic) for this XLII after alignment was +4.5dB over Dolby level. Observe how little compression there is: the +6dB trace runs almost 6dB above the 0dB trace.

Type I was set for Maxell UR (1994). This entailed tweaking the one bias pot, and nothing done for levels. Even so the responses are nicely flat, with the expected channel imbalance in the high treble, and even with Dolby the results are useful. The +6dB trace is 2dB below its ideal level, there is compression indeed. The MOL was +2.7dB.

Finally, with nothing left to tweak for metal tape, all I could do was put in a Sony Metal XR (1992) and verify the resulting responses, hoping for the best. Again the result was quite reasonable, bar the channel imbalance. The -20dB response runs to 19kHz or so, and at 0dB the -3dB point lies above 10kHz. The measured MOL was +6dB.

There was one remaining problem: a bit of hum pickup during replay. This was at 50Hz and odd harmonics, so probably radiated from the power transformer. I spent a lot of time looking for mu-metal to build a shield around the transformer. Eventually I found something interesting here: https://www.reichelt.de/magnetfeldabschirmfolie-mu-metall-ac-dc-aar-ms-f-p154826.html?, a thin sheet of 155 x 1000 mm.

For testing I cut off a strip of 60 x 155 mm, and put that as a wall between transformer and transport, in the already available space. This was the simplest of solutions, but it lowered the 50Hz component of the hum by a very audible 6dB.

I tried a second layer of mu-metal, touching the first one, but the measurement was not clearly showing any benefit. Maybe 1-2dB, not sure.

For the final solution I took two layers of mu-metal, each wrapped in isolating tape (avoiding any accidents in that close proximity to the transformer, mains wiring, and supply board), and with a grounding wire connecting each strip to the control board's ground. The metal strips were of course secured in place.

That's about it. Time to close the lid and label the patient ...